The art of sliding into bases is one of the most thrilling and technically demanding aspects of baseball. Players often execute slides to avoid tags or reach a base safely, but the physics behind this maneuver is rarely discussed in detail. One critical factor influencing a successful slide is the coefficient of friction between the player’s body and the ground. Understanding and measuring this friction can provide valuable insights into player performance, injury prevention, and even equipment design.

The Science Behind Sliding Friction

When a player slides into a base, the interaction between their body and the playing surface generates friction. This frictional force determines how quickly the player decelerates and whether they maintain control during the slide. The coefficient of friction, a dimensionless value representing the ratio of frictional force to normal force, varies depending on multiple factors. These include the material of the player’s sliding shorts, the condition of the field (dry, wet, or dirt composition), and the player’s technique.

Measuring this coefficient isn’t as straightforward as lab-based friction tests. Unlike controlled experiments with uniform materials, baseball slides involve dynamic human movement and unpredictable surface conditions. Researchers must account for variables such as player speed, body angle, and even the way cleats dig into the dirt before initiating the slide. Advanced motion capture systems and force plates have been employed in recent studies to gather precise data on these interactions.

Field Conditions and Their Impact

The type of surface a player slides on dramatically affects friction. Natural grass fields with clay-based infield dirt behave differently than artificial turf. On a well-maintained dirt infield, moisture content plays a crucial role—too dry, and the surface becomes loose and abrasive; too wet, and it turns slick, reducing friction unpredictably. Groundskeepers often tailor field conditions to suit a team’s playing style, which inadvertently influences how players slide.

Artificial turf, increasingly common in modern stadiums, introduces another layer of complexity. While it offers consistency in texture, its synthetic fibers interact differently with sliding fabrics compared to natural surfaces. Some players report that slides on turf feel faster but also increase the risk of abrasion burns. Studies comparing friction coefficients between turf and natural dirt have yielded mixed results, suggesting that player preference and adaptability may be just as important as raw data.

Equipment Innovations and Player Safety

Sliding shorts and pants are designed with friction in mind. Traditional materials like polyester blends dominate the market, but recent advancements incorporate low-friction panels in strategic areas. These panels aim to reduce abrasion while maintaining enough grip to allow controlled deceleration. Manufacturers experiment with materials such as ultra-high-molecular-weight polyethylene (UHMWPE), known for its durability and slickness, to optimize slide performance.

However, reducing friction too much can backfire. Players rely on some degree of resistance to stabilize their bodies during slides. Without it, they risk over-sliding past the base or losing balance entirely. The challenge lies in finding the sweet spot where friction minimizes injury risk without compromising control. Some teams now collaborate with biomechanics experts to customize sliding gear based on individual player styles and field conditions they frequently encounter.

Player Technique: The Human Variable

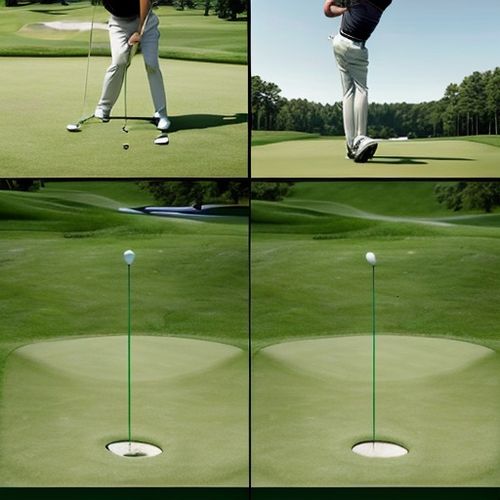

Even with ideal field conditions and advanced equipment, player technique remains the most significant factor in sliding friction. The angle at which a player’s leg makes contact with the ground, the distribution of their weight, and the timing of the slide all influence the effective coefficient of friction. Veteran players often develop an intuitive sense of how to adjust their slides based on the feel of the field, something that’s difficult to quantify but crucial for consistent performance.

Coaches now incorporate slide training with friction awareness in mind. Drills that simulate different field conditions help players adapt their techniques accordingly. High-speed cameras capture slides frame-by-frame, allowing players and coaches to analyze how minor adjustments in body position affect slide efficiency. This hands-on approach complements laboratory research, bridging the gap between theoretical friction coefficients and real-world application.

The Future of Friction Measurement in Baseball

As sensor technology advances, so does the potential for more accurate friction measurement during actual gameplay. Embedded wearable sensors could provide real-time data on the forces experienced during slides, offering immediate feedback to players and trainers. Combined with machine learning algorithms, this data might reveal patterns linking specific friction ranges to optimal slide outcomes or injury risks.

Meanwhile, ongoing research into material science promises further innovations in sliding apparel. Smart fabrics that dynamically adjust their friction properties based on field conditions could one day become a reality. Until then, the intersection of physics, athletics, and equipment design continues to evolve, driven by the pursuit of that perfect slide—fast enough to beat the throw, controlled enough to stay on base, and safe enough to walk away from.

By William Miller/May 9, 2025

By John Smith/May 9, 2025

By Lily Simpson/May 9, 2025

By Eric Ward/May 9, 2025

By Eric Ward/May 9, 2025

By Victoria Gonzalez/May 9, 2025

By Samuel Cooper/May 9, 2025

By Emily Johnson/May 9, 2025

By Noah Bell/May 9, 2025

By Joshua Howard/May 9, 2025

By Eric Ward/May 8, 2025

By Joshua Howard/May 8, 2025

By George Bailey/May 8, 2025

By Grace Cox/May 8, 2025

By Michael Brown/May 8, 2025

By Daniel Scott/May 8, 2025

By Rebecca Stewart/May 8, 2025

By Victoria Gonzalez/May 8, 2025

By Emily Johnson/May 8, 2025

By Olivia Reed/May 8, 2025